A manual machine press is a versatile mechanical tool used for shaping, molding, and assembling materials. It offers precision, cost-effectiveness, and ease of use across various industries.

1.1 Definition and Basic Functionality

A manual machine press is a mechanical device operated by hand or lever to apply controlled force for shaping, pressing, or assembling materials. It uses a combination of levers and gears to amplify force, enabling precise control over pressure and alignment, making it ideal for various industrial and craft applications.

1.2 Historical Background and Evolution

Manual machine presses originated in the early industrial era, evolving from simple hand tools to more sophisticated devices. Initially used for metalworking, they gained prominence in the 19th century for their versatility in shaping and assembling materials. Over time, advancements in design and materials have enhanced their efficiency and user-friendliness.

Types of Manual Machine Presses

Manual machine presses include mechanical, hydraulic, and pneumatic types, each designed for specific tasks. They vary in operation, offering precision, strength, or consistent pressure for diverse industrial and crafting needs.

2.1 Mechanical Presses

Mechanical presses use a flywheel and crankshaft mechanism to generate force. They are ideal for metal stamping and shaping, offering high precision and control. These presses are commonly used in metalworking and fabrication, providing durable and consistent results with minimal maintenance required.

2.2 Hydraulic Presses

Hydraulic presses utilize fluid pressure to apply force, offering smooth and consistent operation. They are suitable for heavy-duty tasks like metal forming and plastic molding. These presses provide adjustable pressure control and are known for their efficiency in handling large-scale industrial applications with precision and reliability.

2.3 Pneumatic Presses

Pneumatic presses operate using compressed air, offering high-speed and energy-efficient solutions. Ideal for lighter applications, they provide precise control and are commonly used in metal fabrication, plastic molding, and small-scale manufacturing. Their clean operation and quick cycling make them suitable for tasks requiring rapid, repeatable force application with minimal maintenance;

Applications of Manual Machine Presses

Manual machine presses are widely used in metalworking, plastic molding, and crafting. They enable precise shaping, assembly, and forming of materials, making them essential tools in fabrication, prototyping, and small-scale manufacturing processes.

3.1 Metalworking and Fabrication

Manual machine presses are essential in metalworking for bending, shaping, and assembling metal components. They are used for tasks like punching holes, forming sheets, and fitting parts together, providing precision and control for both small-scale and industrial fabrication needs. Their versatility makes them a key tool in various metalworking projects.

3.2 Plastic Molding and Shaping

Manual machine presses are widely used in plastic molding and shaping for creating custom molds, forming plastic sheets, and embedding components. They offer precise control over pressure and temperature, making them ideal for crafting intricate plastic parts and prototypes, enhancing efficiency in small-scale production and hobby projects.

3.3 Craft and Hobby Projects

Manual machine presses are essential tools for craft and hobby projects, enabling enthusiasts to shape metal, plastic, and other materials with precision. They are ideal for creating custom jewelry, miniatures, and intricate designs, offering a creative outlet for DIY enthusiasts and artisans seeking to bring their imaginative ideas to life.

Operating a Manual Machine Press

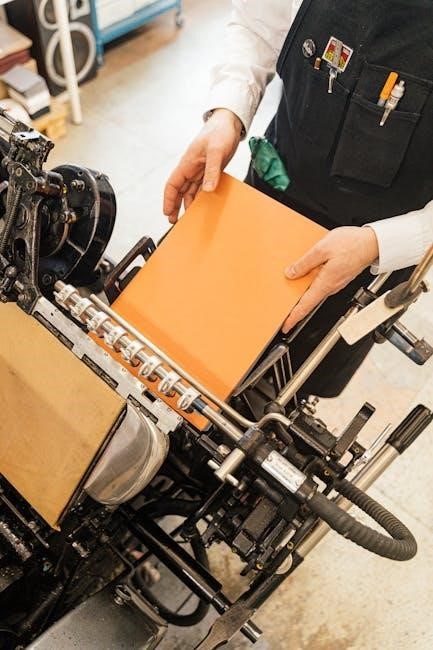

Operating a manual machine press involves following a step-by-step guide to ensure safe and effective use. Adjust pressure settings carefully and always adhere to safety guidelines.

4.1 Step-by-Step Guide to Using a Manual Press

Start by preparing the workpiece and ensuring the press is on a stable surface. Clamp the material firmly, adjust the press settings according to the task, and apply pressure slowly. Release carefully after completion, ensuring safety throughout the process.

4.2 Adjusting Pressure and Settings

Adjusting pressure and settings on a manual press involves checking manufacturer guidelines, using adjustment knobs or levers, and monitoring pressure levels. Ensure proper alignment and safety measures are in place to avoid accidents. Always test with minimal pressure before full application.

4.3 Safety Precautions During Operation

Always wear protective gear, including gloves and safety glasses. Ensure all guards are in place and functioning. Keep loose clothing tied back and avoid jewelry that could catch. Maintain awareness of moving parts and never reach into the press while it’s active. Follow manufacturer guidelines and ensure emergency stops are accessible.

Advantages of Manual Machine Presses

Manual machine presses offer cost-effectiveness, precision, and portability, making them ideal for various applications. They provide consistent results and are versatile for metalworking, crafting, and small-scale production needs.

5.1 Cost-Effectiveness

Manual machine presses are budget-friendly, requiring minimal initial investment and low maintenance. Their durability ensures long-term savings, making them a practical choice for small workshops and hobbyists seeking affordable precision and reliability in various applications.

5.2 Precision and Control

Manual machine presses provide exceptional precision, allowing operators to apply controlled force for accurate results. Their mechanical advantage ensures consistent pressure, making them ideal for intricate tasks like metalworking and crafting. This level of control minimizes errors and enhances productivity in various applications.

5.3 Portability and Versatility

Manual machine presses are lightweight and compact, making them easy to transport and use in various settings. Their versatility allows them to handle diverse tasks, from metal fabrication to crafting, ensuring adaptability for both professional and hobbyist applications. This portability enhances convenience and efficiency in workshops or DIY projects.

Maintenance and Repair

Regular lubrication of moving parts and thorough cleaning ensure optimal performance. Inspect for wear and replace damaged components promptly to maintain functionality and extend equipment lifespan effectively.

6.1 Daily Maintenance Tips

Perform daily checks on lubrication levels and ensure all moving parts are well-greased. Clean surfaces regularly to prevent debris buildup. Inspect for wear and tear, addressing minor issues promptly to avoid major repairs. Proper storage and organization of tools also contribute to efficient machine operation and longevity.

6.2 Troubleshooting Common Issues

Identify pressure problems by checking fluid levels and pump operation. Address alignment issues by recalibrating or adjusting components. Inspect for leaks in hydraulic or mechanical systems and tighten connections. Regularly clean and lubricate moving parts to prevent friction. Consult the user manual for specific solutions or contact a professional for persistent issues.

6.3 Lubrication and Parts Replacement

Regular lubrication of moving parts ensures smooth operation and prevents wear. Inspect and replace worn components promptly to maintain efficiency; Check hydraulic systems for leaks and tighten connections as needed. Always consult the manual for specific part replacement guidelines and recommended maintenance schedules. Proper care extends the machine’s lifespan and ensures reliability.

Safety Guidelines

Always follow safety protocols when operating a manual machine press. Refer to the safety guide in the product box for warnings and important information to ensure safe usage.

7.1 Preventing Accidents and Injuries

Preventing accidents with a manual machine press requires proper training, adherence to safety guidelines, and regular equipment inspection. Always use safety guards, avoid loose clothing, and ensure a clean workspace. Following manufacturer instructions and maintaining focus during operation minimizes injury risks and ensures safe, efficient performance.

7.2 Proper Use of Safety Guards

Always ensure safety guards are securely in place before operating a manual press. Never bypass or remove guards, as they protect against injuries. Regularly inspect guards for damage and ensure proper alignment. Train all users on guard functionality to maintain a safe working environment and prevent accidents during operation.

7.3 Emergency Stop Procedures

In case of an emergency, immediately press the emergency stop button to halt the machine. Ensure all operators are trained on emergency procedures. Regularly test the E-Stop functionality and ensure it is easily accessible. Always follow manufacturer guidelines and safety protocols to prevent accidents and ensure quick response during critical situations.

DIY Projects Using Manual Press

A manual press is a versatile tool for creative DIY projects, enabling metal fabrication, plastic shaping, and crafting jewelry or small parts with precision and ease.

8.1 Metal Fabrication Projects

Manual presses excel in metal fabrication, allowing precise shaping and forming of complex designs. Craftsmen can create custom parts, such as brackets, frames, and decorative items. The tool’s portability and control make it ideal for intricate metalwork, enabling professionals to produce high-quality components efficiently in various settings, from workshops to home-based projects.

8.2 Custom Tooling and Mold Making

Manual presses are invaluable for creating custom tooling and molds, offering precision and control. They enable craftsmen to shape materials like metal and plastic into intricate designs, perfect for prototyping or small-scale production. This flexibility allows for tailored solutions, making manual presses a key tool in specialized manufacturing and artisanal projects.

8.3 Crafting Jewelry and Small Parts

Manual machine presses are versatile tools for crafting jewelry and small parts, offering precision and control. They enable artisans to shape, stamp, and assemble intricate designs with ease. Ideal for small-scale production, these presses are perfect for creating custom jewelry, miniaturized components, and detailed embellishments, making them essential for craft workshops and DIY enthusiasts;

Future Trends in Manual Press Technology

Future trends include integration with smart technology, eco-friendly materials, and compact designs. These advancements aim to enhance efficiency, sustainability, and user experience in manual machine press operations.

9.1 Integration with Smart Technology

Manual machine presses are evolving with IoT connectivity, enabling remote monitoring and control via smartphones. The ThinQ app allows users to track performance and adjust settings, optimizing workflows. Real-time data analysis enhances efficiency and precision, paving the way for smarter, more sustainable manufacturing processes in the future.

9.2 Eco-Friendly and Sustainable Materials

Modern manual presses increasingly utilize eco-friendly materials like recycled metals and biodegradable plastics. These sustainable options reduce environmental impact without compromising performance. Innovations in material science are driving greener manufacturing, aligning with global efforts to minimize waste and promote environmental responsibility in industrial applications.

9.3 Compact and Space-Saving Designs

Advancements in manual press design focus on creating compact, space-saving machines. These models are ideal for small workshops or home-based operations, offering portability without compromising functionality. Improved engineering enables efficient performance in limited spaces, catering to modern demands for versatility and reduced footprint while maintaining productivity and precision.

Troubleshooting Common Issues

Troubleshooting manual machine presses involves identifying issues like misalignment, pressure fluctuations, or mechanical malfunctions. Regular maintenance and timely repairs ensure optimal performance and minimize operational downtime effectively.

10.1 Identifying and Solving Pressure Problems

Pressure issues in manual presses often stem from improper calibration or worn components. Regular inspection of seals and hydraulic lines ensures optimal pressure. Adjusting the pressure settings and lubricating moving parts can resolve sticking or inconsistent force application.

10.2 Addressing Alignment and Accuracy Issues

Alignment problems often arise from improperly set dies or uneven workpiece placement. Regularly inspect and adjust the press’s alignment pins and guide rails. Calibrating the press and using precision fixtures can enhance accuracy. Operator training is essential to ensure consistent and precise results during operation.

10.3 Fixing Hydraulic or Mechanical Leaks

Identify the source of the leak by inspecting hydraulic lines, seals, and connections. Replace worn or damaged components, ensuring proper tightening of fittings. Use compatible replacement parts and consult the manual for specific instructions. Regular maintenance, such as fluid level checks and filter replacements, can prevent future leaks and extend machine longevity.

Manual machine presses are essential tools for precision and efficiency in various industries. Their versatility, ease of use, and cost-effectiveness make them invaluable for both professionals and hobbyists alike.

11.1 Summary of Key Points

Manual machine presses are versatile tools offering precision and efficiency. They are cost-effective, portable, and suitable for metalworking, plastics, and crafts. Regular maintenance and safety practices ensure optimal performance and longevity, making them indispensable in various industries and DIY projects.

11.2 Final Thoughts on Manual Machine Press Usage

Manual machine presses are indispensable tools for professionals and hobbyists alike, offering precision and adaptability. Their user-friendly design makes them ideal for diverse projects, from metalworking to crafts. Embracing future trends like smart technology and eco-friendly materials ensures their continued relevance. Always prioritize safety and proper usage for optimal results.