Tank gauging measures liquids in storage tanks, determining volume and mass through level, temperature, and pressure assessments. It’s crucial for inventory control, safety, and operational efficiency, with a detailed guide available for engineers.

1.1 Definition and Purpose

Tank gauging is the process of measuring liquid properties, such as level, temperature, and pressure, in storage tanks to determine the volume and mass of the liquid. Its primary purpose is to ensure accurate inventory management, prevent overfilling, and comply with safety standards. Advanced systems provide real-time data, enabling efficient operational control and custody transfer. This process is essential for maintaining safety, optimizing resources, and meeting regulatory requirements in various industrial settings, including refineries and petrochemical plants.

1.2 Importance in Industrial Processes

Tank gauging plays a vital role in industrial operations by ensuring accurate measurement and control of liquid resources. It supports inventory management, prevents overfilling, and ensures compliance with safety and environmental regulations. In refineries, terminals, and depots, gauging systems provide critical data for efficient operations, legal custody transfer, and process optimization. This ensures operational safety, reduces risks, and enhances overall efficiency, making it a cornerstone of modern industrial practices.

Tank Gauging Technologies

Tank gauging technologies include manual methods, float gauges, servo gauges, radar gauges, and automated systems, providing precise measurements for inventory control, safety, and operational efficiency.

2.1 Manual Gauging Methods

Manual gauging involves using tools like dip tapes to measure liquid levels in tanks. This traditional method relies on human intervention, offering a straightforward approach for basic measurements. It is commonly used in smaller facilities or as a backup to automated systems. Manual gauging provides essential data for inventory management and is often employed in industries where simplicity and cost-effectiveness are prioritized. Despite advancements in technology, manual methods remain relevant for their ease of use and reliability in specific scenarios.

2.2 Float Gauges

Float gauges operate by using a floating element that rises and falls with the liquid level in the tank. This movement is mechanically or electronically translated into a readable measurement. They are widely used for their simplicity and reliability in various industrial applications. Float gauges provide accurate and continuous monitoring of liquid levels, making them ideal for tanks containing oils, chemicals, and other fluids. Their design ensures minimal maintenance and long-term durability, enhancing operational efficiency in diverse storage environments.

2.3 Servo Gauges

Servo gauges utilize a servo mechanism to measure liquid levels in storage tanks with high precision; They are widely used in industrial applications due to their accuracy and reliability. The servo system automatically adjusts to the liquid’s surface, providing continuous and real-time data. These gauges are particularly effective in scenarios requiring precise volume assessment, such as in oil and petrochemical industries. Their ability to integrate with automated systems makes them a preferred choice for modern tank management solutions, ensuring efficient and accurate liquid measurement.

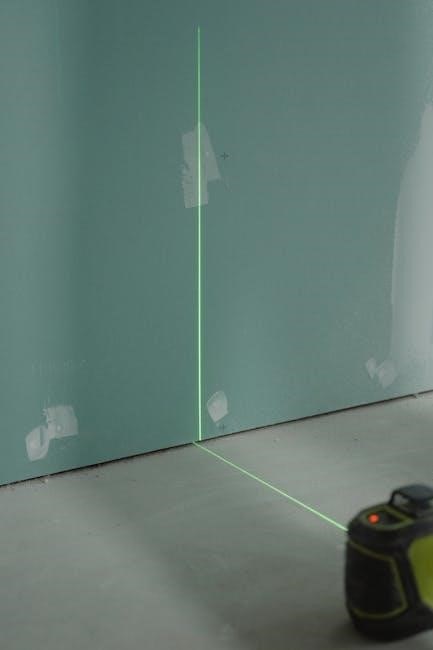

2.4 Radar Gauges

Radar gauges employ microwave technology to measure liquid levels in storage tanks with high accuracy and reliability. They operate by emitting radar waves that reflect off the liquid’s surface, calculating the level based on the time delay. These gauges are resistant to dust, vapor, and temperature variations, making them ideal for challenging environments. Radar technology ensures non-contact measurement, reducing maintenance and increasing safety. They are widely used in oil, gas, and chemical industries for precise volume assessment and inventory management, offering a robust solution for tank gauging needs.

2.5 Automated Gauging Systems

Automated gauging systems integrate advanced technologies like radar, servo, and float gauges with software for real-time monitoring and data analysis. These systems enhance accuracy and efficiency by minimizing human intervention, ensuring continuous measurement and reducing errors. They are scalable and adaptable to various tank sizes and liquids, offering features like overfill prevention and inventory management. Automated solutions are ideal for industries requiring precise, reliable, and efficient tank measurement, streamlining operations and improving safety standards across industrial applications.

Engineering Standards and Approvals

Engineering standards and approvals ensure tank gauging systems meet safety, accuracy, and efficiency requirements. Compliance with certifications is crucial for reliable performance and legal adherence.

3.1 Relevant Industry Standards

Relevant industry standards for tank gauging ensure accuracy, safety, and compliance. Standards like API and ISO provide guidelines for system performance, accuracy, and safety features. Compliance with these standards is critical for legal and fiscal requirements, ensuring reliable measurements. By adhering to these benchmarks, industries maintain operational efficiency and minimize risks. Proper certification ensures systems meet international standards, fostering trust and consistency across operations. These standards are essential for optimal tank management and regulatory adherence.

3.2 Certification and Compliance

Certification ensures tank gauging systems meet industry standards, guaranteeing reliability and safety. Compliance involves adhering to regulations like API and ISO, which validate system performance and accuracy. Third-party certifications are crucial for legal and fiscal requirements, ensuring measurements are trustworthy. Compliance also involves regular audits and maintenance to uphold standards. By achieving certification, organizations demonstrate commitment to quality and safety, minimizing risks and ensuring operational excellence. This process is vital for maintaining integrity in industrial operations and regulatory environments.

Overfill Prevention and Safety

Overfill prevention is critical for tank safety, preventing spills and environmental hazards. Advanced systems detect high levels, ensuring compliance with safety standards and protecting assets.

4.1 Safety Measures in Tank Gauging

Tank gauging involves critical safety measures to prevent accidents. Proper installation of overflow detectors and automated shut-off valves ensures tanks do not exceed safe levels. Regular maintenance of gauging systems is essential to maintain accuracy and reliability. Training personnel on emergency procedures and adhering to industry standards further enhances safety protocols. Implementing these measures helps protect both personnel and the environment from potential hazards associated with liquid storage.

4.2 Overfill Prevention Systems

Overfill prevention systems are critical for ensuring the safe operation of storage tanks. These systems utilize advanced technologies such as radar gauges, float gauges, and automated alerts to monitor liquid levels in real-time. By implementing these solutions, facilities can prevent overflow incidents, reduce environmental risks, and comply with safety regulations. Regular system checks and maintenance are essential to ensure the reliability and effectiveness of overfill prevention mechanisms, safeguarding both equipment and personnel from potential hazards.

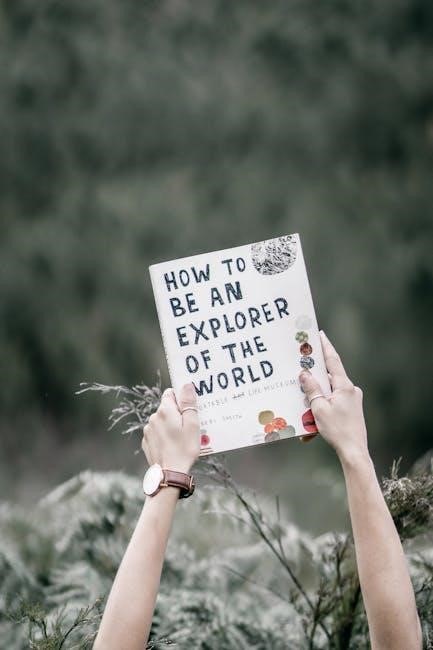

Ear Gauging (Ear Stretching)

Ear gauging involves gradually enlarging pierced earlobes using specialized tools. It typically starts at 16-14 gauge, with safety and aftercare essential for healthy results.

5.1 Basics of Ear Stretching

Ear stretching, or gauging, involves gradually enlarging pierced earlobes to accommodate larger jewelry. It typically starts with a standard piercing gauge (18-20) and progresses to larger sizes. To begin, a taper or needle is used to create space for the new jewelry. Materials like glass, stainless steel, or silicone are recommended for comfort and safety. The process requires patience, as stretching too quickly can cause damage. Proper aftercare, including cleaning and allowing time to heal, is essential for healthy results. Consulting a professional is advised for best outcomes.

5.2 Safe Practices for Ear Gauging

Safe ear gauging involves gradual stretching to avoid tissue damage. Start with a standard piercing gauge (18-20) and progress slowly. Use high-quality, non-irritating materials like glass, stainless steel, or silicone. Sanitize equipment and jewelry to prevent infections. Avoid over-stretching, as this can cause tears or inflammation. Allow adequate healing time between stretches, typically 6-12 months. Clean the area regularly with saline solution and avoid tight or restrictive jewelry during the healing process. Patience and proper aftercare are essential for successful results. Always consult a professional for guidance.

5.3 Choosing the Right Materials

Selecting the right materials is crucial for safe and successful ear gauging. Opt for high-quality, body-friendly options like borosilicate glass, solid stainless steel, or silicone. Avoid low-quality plastics or metals that can cause allergic reactions or infections. Glass plugs are ideal due to their smooth finish and ease of cleaning. Stainless steel is durable and hypoallergenic. Silicone is flexible and comfortable for healing. Always ensure jewelry is free from sharp edges and properly polished to prevent irritation or damage to the ear tissue during stretching or aftercare. Material choice significantly impacts comfort and safety.

5.4 Hygiene and Aftercare

Proper hygiene and aftercare are essential for successful ear gauging. Clean the area regularly with saline solution to prevent infections. Avoid harsh chemicals, as they can irritate the skin. Keep the jewelry clean and dry, and avoid touching it unnecessarily. Regularly wash your hands before handling the jewelry to minimize the risk of contamination. Proper aftercare ensures the piercing heals smoothly and reduces the chance of complications. Consistent care routines promote healthy stretching and long-term comfort.

Best Practices and Future Trends

Best practices in gauging involve accurate measurements, regular maintenance, and adherence to safety standards. Future trends include advanced automation, IoT integration, and AI-driven systems for enhanced efficiency and safety.

6.1 Optimizing Gauging Processes

Optimizing gauging processes involves implementing advanced technologies and streamlined workflows. By integrating automated systems and leveraging real-time data, accuracy and efficiency are significantly enhanced. Regular calibration ensures precision, while training personnel on the latest tools minimizes errors. Additionally, adopting predictive maintenance reduces downtime and extends equipment lifespan. These improvements collectively contribute to safer, more reliable, and cost-effective operations across various industries.

6.2 Emerging Technologies in Gauging

Emerging technologies in gauging include advanced radar systems, automated measurement tools, and intelligent software solutions. These innovations enhance accuracy, reduce manual intervention, and improve safety. Radar gauges offer non-contact level measurement, while automated systems integrate with predictive analytics for real-time insights. Additionally, advancements in servo and float gauges provide higher precision and durability. These technologies are transforming industries by enabling smarter, more efficient, and scalable gauging solutions.